NetSuite ERP software is a fully cloud-based omnichannel solution with comprehensive features and capabilities to take care of everything in the manufacturing and business process. Instead of handling different legacy tools for CRM, supply chain management, eCommerce management, accounting, and financial management, with NetSuite implementation partner and its capabilities a manufacturing business gets all these functionalities inbuilt.

NetSuite offers a Software as a Service (SaaS) platform that helps you to run the entire manufacturing business with every tool you require for different processes. The open architecture along with an unlimited scope of customization backed by the ease of integration with existing software systems made NetSuite ERP so popular among the manufacturing stalwarts across niches.

What Value Propositions NetSuite ERP Manufacturing Offers?

It is not difficult to understand that the business processes across all sizes and categories of manufacturing companies are increasingly becoming complex with the advent of new technologies, new market dynamics, and evolving supply chain requirements.

Earlier to deal with these complexities brands used to rely on different software tools for inventory management, warehousing, production management, accounting and finance, supply chain management, etc. Obviously, the use of multiple software tools created process silos because of the fragmented nature of data management. This is where the need for a comprehensive ERP software with every kind of feature and functionalities came to notice.

NetSuite ERP system just delivers a comprehensive and robust cloud-based platform to take care of each and everything their business processes need.

- With NetSuite you have all features and functionalities integrated and out of the box. For lean and functionally optimized manufacturing process you have integrated work orders, assembly line management, demand-based replenishment, and everything you require.

- The ERP solution apart from addressing the core requirements corresponding to manufacturing processes also takes care of all other business processes and the entire product life cycle.

- NetSuite offers a highly agile, proactive, and thoroughly customizable solution to help with everything a business needs.

- This is a truly global ERP platform that works irrespective of any location, currency, industry, and location-specific protocols and practices.

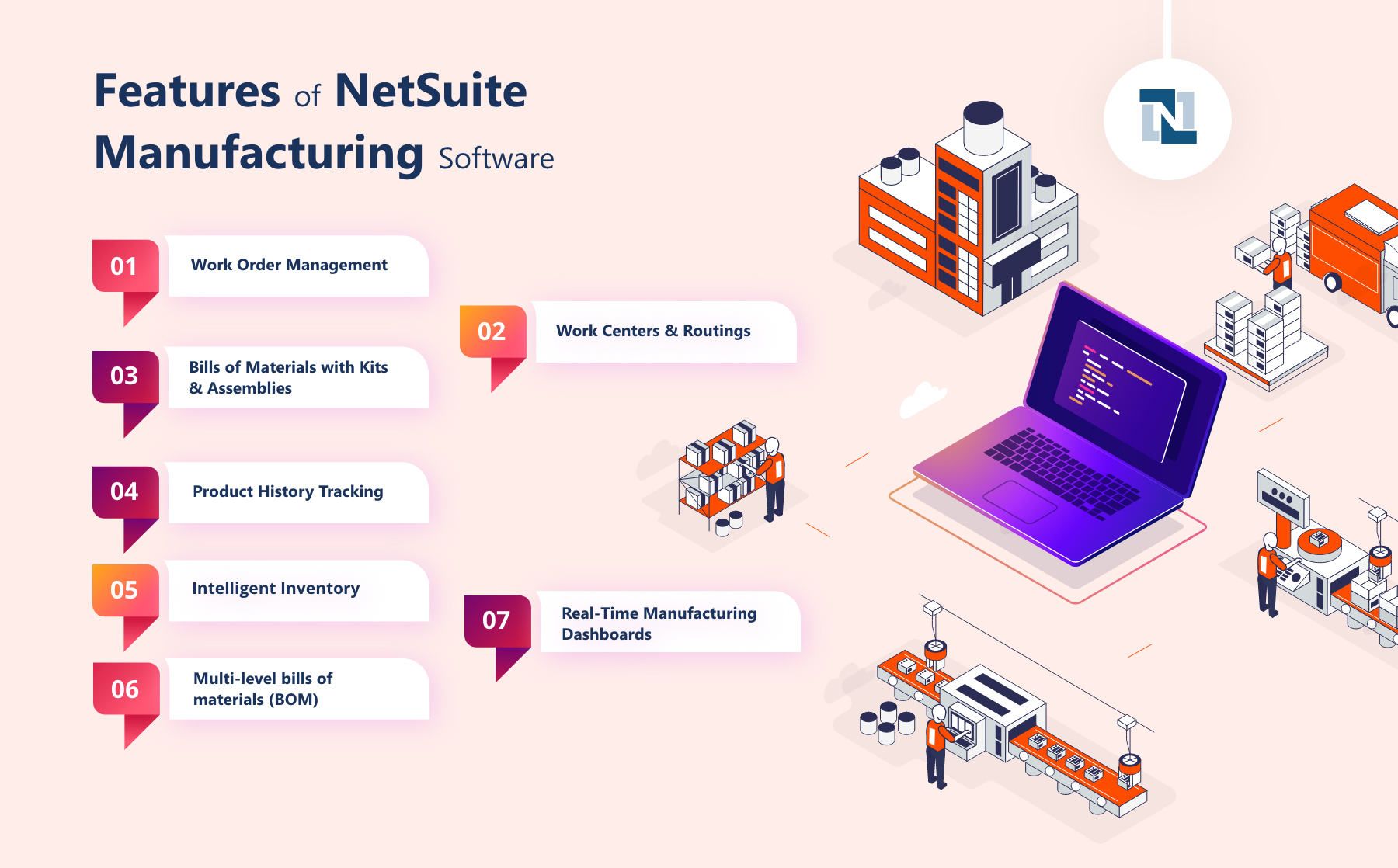

9 Leading NetSuite Manufacturing Software Features That Create Ease

As of now, you must have understood the comprehensive nature of the NetSuite ERP that practically leaves no unattended feature that manufacturing companies need. This is the most complete set of tools that practically knows no limits in terms of accommodating your requirements.

Here are the key NetSuite manufacturing features to watch out for.

Customer Relationship Management (CRM)

NetSuite comes with an inbuilt Customer Relationship Management (CRM) suite to keep communicating with customers, incorporating their feedback, and building customer loyalty over time.

Production Data Management

In this robust manufacturing software suite, you can manage, store, and keep track of all production data in just one place.

Order Management

The order management feature of the software will help businesses to process the orders at right time and ensure zero delays streamlined processing.

Making Plans and Schedules

NetSuite comes with robust capabilities to make new production and business plans and schedule tasks and responsibilities as per the real-time data inputs concerning demand and supply.

Procurement Management

NetSuite comes with a standalone procurement management feature to deal with the vendors and their respective purchasing processes so that you can ensure the best competitive market price and smooth and timely delivery.

Production Management

The production management feature of NetSuite allows easily creating work orders and releasing, updating, and managing them throughout the process.

Supply Chain Management (SCM)

With NetSuite, you can fully control and keep track of your entire outsourced manufacturing processes and the entire chain of suppliers leading to the production facility.

Retail Store Control

NetSuite offers real-time visibility of retail sales data and the movement of the inventory to help a manufacturing company ensure a streamlined process.

Quality Assurance (QA)

NetSuite offers integrated Quality Assurance (QA) and quality control tools to help monitor the entire manufacturing process and quality parameters at every stage.

6 Top Benefits of NetSuite For Your Manufacturing Business

With a rich reserve of integrated features and functionalities, NetSuite helps any manufacturing company to streamline the entire process while maintaining strict controls on resources, order management, and quality.

Here we briefly explain the key benefits of NetSuite ERP for manufacturing businesses.

Bill of Materials (BOM) Management

Bill of Materials or BOM management is a crucial task of any manufacturing process. By using time-tested industry-acclaimed algorithms NetSuite helps to manage the supply of materials as per the demands and requirements of maintaining safety stock.

Cost and Resource Analysis

Since the timely analysis of resources and cost is crucial for a manufacturing company to stay competitive, an ERP software suite as comprehensive as NetSuite included a cost analysis tool powered by real-time updates of material and costing data. This will also help to carry out inventory tracking as well as tracking the cost of various items in different layers.

WIP Operations

A manufacturing company needs to track real-time data of the undergoing manufacturing process or production at the Work in Progress (WIP) stage. NetSuite offers 360-degree round the clock visibility of production and manufacturing data to stay updated about each and every aspect of the production process.

This gives a manufacturing business optimum control in respect of taking up orders for production and creating priorities.

Managing Manufacturing Units

The manufacturing units comprising machines and workers for dealing with specific tasks are also referred to as Work centers. NetSuite helps to manage different Work Centers and help to route tasks as per the requirements of the manufacturing process. This particularly helps in managing complex work orders involving too many tasks and different processes.

Accurate Forecasting

NetSuite gives manufacturers additional capabilities to automate the entire business process across multiple channels. Through this companies can actually align their manufacturing process with the demands created by marketing campaigns and market responses. Thanks to the alignment of the marketing team, inventory management, and manufacturing process, more accurate predictions, and forecasts can be made to help the company get ready to deliver.

NetSuite enables manufacturers to proactively manage inventory and help them understand planned versus actual costs for better planning and forecasting.

Quality Assurance

Maintaining consistent quality in production is the key to better warehousing and more professional inventory management. Since this holistic quality assurance approach requires a commitment at every level of a company, an ERP software suite with inbuilt quality management tools can play an important role. This is exactly what NetSuite Quality management solution does for a manufacturing company.

How Does The NetSuite Manufacturing Software Work?

NetSuite offers a consolidated solution with several layers and phases to deal with different requirements for the manufacturing companies to scale their business. The NetSuite Manufacturing software works through the following steps.

- In the very first step, it is given the priority that manufacturers can access the data on customers, orders, items, and inventory through a single interface.

- At the second step, manufacturers through this software platform can incorporate e-commerce or different omnichannel interfaces to ensure optimum shopping experience for the customers.

- In the following step, the software helps businesses to become free from the constraints and obligations of their legacy software so that they can now address the shortcomings of lack of data visibility through the NetSuite Manufacturing ERP system.

- In the final step, more advanced, defining, and innovative capabilities such as pricing and profit management and business intelligence are introduced within the scope of NetSuite ERP software.

Conclusion

So, NetSuite stands as the most complete software system to deal with every aspect of the manufacturing process. With NetSuite on the side, a manufacturing company can easily break away from the constraints of legacy software tools and advance towards innovation and automation.